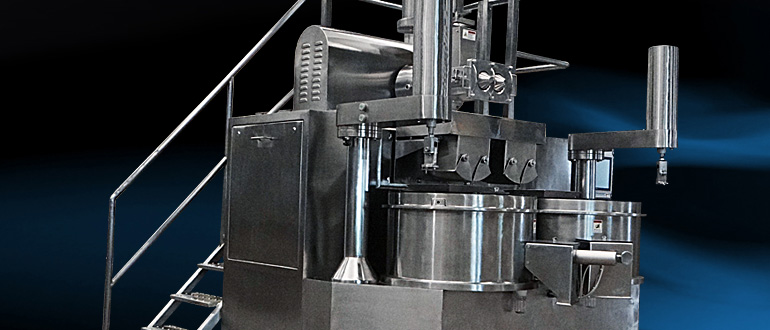

The UMANG Pelletizing System is a turnkey pellet production plant, which combines mixer/granulator, extruder and Spheronizer in a single, integrated process. Continuously wet powders pass through a low-shear radial extruder / cone extruder / pressure extruder / basket extruder. The extrusions are fragmented and formed into pellets in the spheronizer

We have single and twin spheroidization options possible in the integrated system, for high throughput systems we recommend single extruder and twin Spheronizers with twin bucket assembly for feeding the Spheronizers.

Technical Specifications for Extruder Cum Twin Spheronizer:

Models & Specs |

UICE-41 |

The Umang Pharmaceutech Test Station is located in Vasai, THane, conveniently located very close to Mumbai airport, only forty five minutes from Mumbai International Airport. The Test Station's purpose is to assist our Pharmaceutical and Biopharmaceutical Industry customers with feasibility testing of their products on our equipment, and to be a partner with them in the process development as they move forward from the Research and Development stages to clinical production, and eventually into full-scale Manufacturing.

The station combines decades of design and development know-how in the pharmaceutical industry with the very latest in processing equipment to provide you with a unique opportunity for feasibility, development, and small-scale manufacturing of pharmaceutical products.

Your needs are critical and individual. The UMANG Pharmaceutical Test Station has been designed to meet those needs.

Our expertise in formulation development extends to the development of all conventional dosage forms. Our strategic alliances broaden the scope to consider many Novel Drug Delivery Systems (NDDS), including transdermal & liposomal delivery systems. We consider multiple approaches to improve the bioavailability of drugs. We have expertise in improving delivery of poorly soluble/ permeable drugs and the capability to screen potentially innovative drugs based on pharmacokinetic properties. We possess pelletization, drug-layering, particle-coating and other technologies to achieve extended release profiles for tablets or capsules.

Our analytical development services include assay and RS method development and validation, dissolution method development and validation, stability studies as per ICH guidelines, polymorphic form characterization (DSC/TGA/XRD/Microscopy), cleaning validation studies and HPLC to UPLC method conversions.

Are the particles completely spherical after extrusion and spheronization?

Yes, the shape is usually spherical, the major dependence of shape is the formulation development by the individual.

Is extrusion Spheronization used for high drug load formulation only ?

No, it is used for both types for low dose drugs as well as high loaded drugs in pellets .

How is a narrow particle size of a extrusion and spheronization controlled ?

Yes 98-99% can be achieved with a particular range with our guidance and formulation expertise.

Do we provide a Integrated line from mixing to extrusion to spheronization te drying and fluid bed coating ?

Yes, we do offer complete pellet processing lines.

Do you provide twin Spheronizers ?

Yes we provide single, twin and multiple Spheronizers coupled with extruders to give a continuous integrated processing plant.

How often should I clean the machine, are internal parts completely accessible?

Yes as per GMP design.

How quick can we get the delivery for extruder cum twin Spheronizer ?

3-4 weeks depending on the size.

Do you provide twin Spheronizers ?

Yes we provide single, twin and multiple Spheronizers coupled with extruders to give a continuous integrated processing plant.